Lightweight electricity solution emerges for deployed defence units

Defence

A micro gas turbine designed to provide electricity to defence units in the field has been demonstrated to leading industry players in Australia.

Sign up to receive notifications about new stories in this category.

Thank you for subscribing to story notifications.

South Australian company ecoJet Engineering demonstrated its 20kW gas turbine in Canberra last week. The prototype engine system is only about 10 per cent of the weight of a comparable internal combustion diesel engine and can be configured to run on a range of liquid and gaseous fuels, including propane, natural gas and diesel.

ecoJet Engineering received funding at the beginning of this year from the South Australian government and the RAAF Air Warfare Centre Innovation Hub to progress its concept design for a 20kW micro gas turbine into a viable prototype unit. The demonstration unit is the first stage in developing the next generation in deployable power generators for the military.

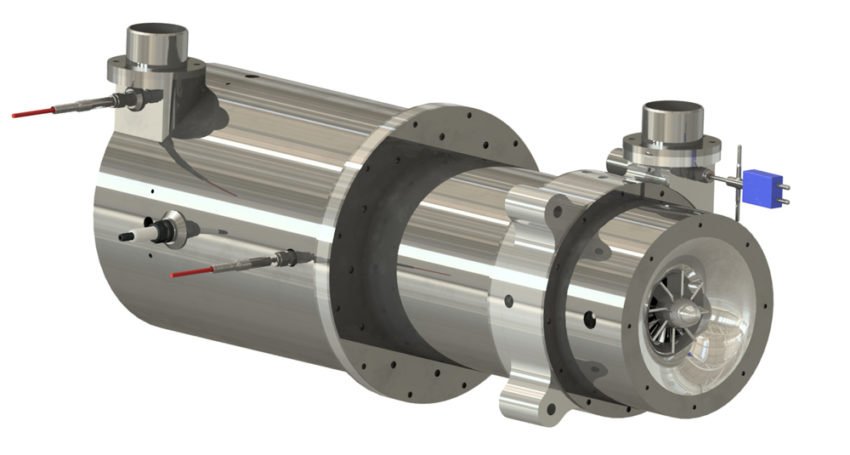

The demonstration unit generator weighs just 48kg, excluding the control system and the fuel tank, compared to 433kg for a current military diesel generator.

It is also about two-thirds the size of the diesel engine, measuring about 600mm long and 250mm wide

ecoJet co-director Alexander Wright said the mobility of the unit, the versatility of the fuel source and potential for more efficient electricity production were among the advantages of the system compared with traditional diesel generators.

ecoJet co-director James Kim with the 20kW micro gas turbine.

He said the demonstration unit already had flow rates comparable with current diesel generators.

“And that’s comparing a prototype unit with a commercially mature product,” Wright said.

“We have a lot of scope for improving our efficiencies above that with things like heat recuperation, bearing advancements, the use of advanced materials such as ceramics and graphenes and multi-stage turbo machinery, which is uncommon for turbines of this scale.

“It is quite efficient and it’s not restrictive of other technologies, it can work quite well in parallel with solar and battery storage so it’s not a competitor to other products exclusively – it can complement other systems.”

The micro turbine works in basically the same way as a typical jet engine where a compressor draws in air and passes it into a combustion chamber where fuel is injected and ignited as it passes through a turbine, creating rotation.

“What we’ve got as part of our novel solution is an integrated shaft assembly where the shaft that connects the turbine and the rotor has an integrated generator attached to it.

“The generator spins with the turbine to create electrical energy from the rotational energy extracted from those combusted gases.”

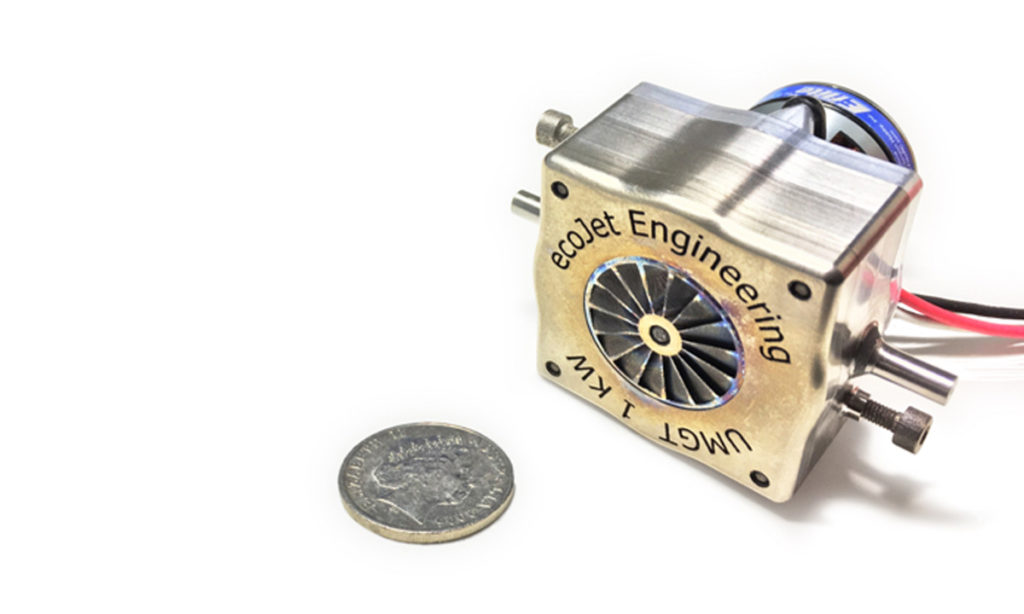

The collaboration between Wright, James Kim and Warren Day that led to the formation of ecoJet Engineering began in 2015 with an Honours project at the University of Adelaide that achieved one of the world’s smallest ultra-micro gas turbines.

Through further studies at the University of South Australia, the collaboration won a Venture Capitalist grant in 2016, which helped launch the company.

ecoJet Engineering also pitched its ultra-micro gas turbine design at this year’s Land Forces event in Adelaide where it was named best innovation.

Major players in the global micro gas turbine industry include Capstone Turbine Corporation (US) and Bladon Micro Turbines (UK) but Wright said their focus was more on industrial applications in the 30kW and greater range.

He said the ecoJet micro gas turbine also had potential as a domestic product to complement renewable technologies such as solar and help households become independent from the electricity grid.

ecoJet’s 1kW ultra micro gas turbine was named best innovation at this year’s Land Forces event in Adelaide.

“A military product is a commercial product with a bunch of extra stuff on top so we can easily tweak it to suit both markets because we are very much looking to break into both areas,” Wright said.

“We’re planning a fairly rapid development timeline and as part of this demonstration we’re looking for further investment from defence and government grants.”

Last Wednesday’s Canberra demonstration included five sessions throughout the day with various stakeholders including senior representatives from all three Australian armed services, the Air Warfare Centre and the Defence Innovation Hub.

“It was a really good opportunity for us to understand from the Defence side where they would use this particular application, what requirements they value more highly such as size over weight or fuel efficiency over fuel versatility so it was really helpful in terms of the next stage of development,” Wright said.

“It was received well and we had some good conversations around some of the funding opportunities for the next stage of developing the technology and the specific capabilities.”

Jump to next article