Digital grape picking tracker targets horticulture industry

Primary Industries

A labour management system designed to improve harvest efficiency for the Australian wine industry is expanding into other agriculture sectors.

Sign up to receive notifications about new stories in this category.

Thank you for subscribing to story notifications.

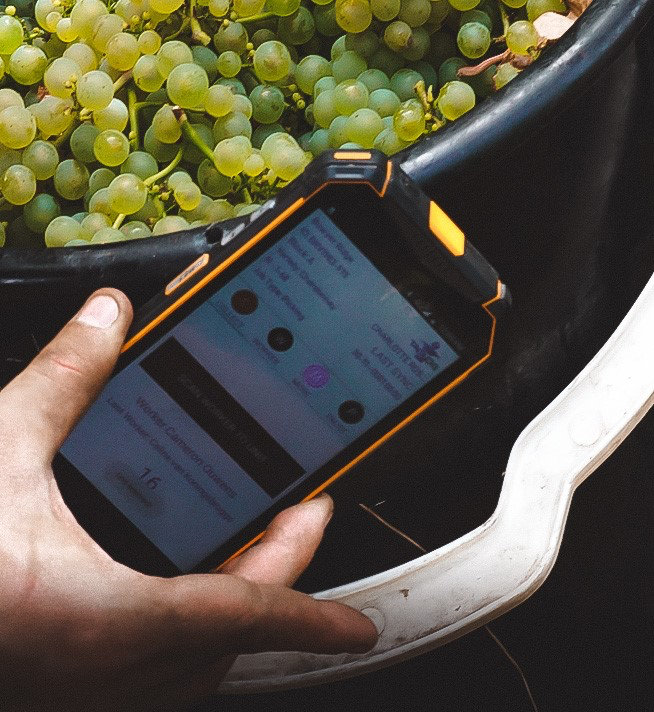

The Taglog system uses cloud-based technology to track the productivity of pickers in the field to ensure they are paid correctly while holding them accountable for the quality of their work.

Accessible through a mobile app, Taglog uses RFID (radio frequency identification), time and GPS stamps and displays them on a real-time operating platform that enables simple piece rate payroll and invoicing.

The startup has been spun out of Adelaide Hills viticulture services business Group Logistics, which is also known as GLOG.

The bulk of Taglog’s 30 customers are vignerons in South Australia but the technology has also been adopted by apple, pear, strawberry and cherry growers.

Field trials of the system began in 2014 after GLOG Managing Director Charles Rosback decided to move the company’s pickers from hourly rate to piecework payments to address productivity issues.

Rosback said the vineyards using the Taglog system during harvest experienced increases in the amount of money workers take home, decreases in the cost of picking grapes and increases in margins.

“Very rarely in any situation do you see a win, win, win so we were fortunate to be able to experience that,” he said.

“We scan the worker and we scan the bucket so we tie that bucket to that worker for a period of time. When a bucket arrives at the trailer and we discover that it’s full of leaves then we can scan that bucket to see who picked it.

“On the back end we can see every worker in the vineyard, what time they logged on, how many buckets they had picked, how many hours they have worked and by putting in the rate we are paying them or the contractor per bucket we can determine the equivalent hourly rate we are paying that person and the average hourly rate that group has earned.”

Rosback said there were a further 35 customers ready to “lock on” and “a couple hundred” more growers or labour companies that had expressed interest from horticulture and other industries.

“We’ve been to a couple of trade shows in Melbourne and Brisbane and we’ve been overrun with interest in what we’re doing,” he said.

“Viticulture is the space that we play in so we’ve initially focused on that but we’re looking to bust out into wider horticulture and beyond.

“When we started building the system we did it in such a way that we could make it fully adaptable for any situation where you’ve got people working in a unit-based working environment so if somebody came to us and said I want to count the number of cars each worker washes in a car wash then we can do that very easily.”

GLOG works with vignerons throughout the Adelaide Hills and surrounding South Australian wine regions as far north as Clare and south to the Coonawarra.

Last vintage, Taglog completed a 30-month trial across 28 Adelaide Hills vineyards to validate the technology. Of those sites, 20 have gone on to become Taglog customers.

Traditional piecework in viticulture has involved giving workers a token such as a pop stick every time they returned a bucket full of grapes.

The initial Taglog system used QR codes to identify the buckets picked by individual workers but Rosback said this was problematic because the worker had no receipt of the work, such as a pop stick.

“Some of the groups wanted to stay with the pop sticks so we gave them a pop stick and we scanned at the same time and at the end of the day the number of pop sticks they handed over was always less than what they had on the screen,” he said.

“They quickly understand that this is a digital technology that provides transparency for the grower and the picker and more importantly it means they can get paid before they leave the vineyard.

“The three things they were looking for were cost, efficiency and quality and this ticks all of those boxes.”

The push for new clients coincides with the introduction of national labour hire licensing laws, which came into effect in South Australia on November 1, and the lead up to Australia’s 2020 grape harvest, which will begin in late January and go through to the end of April.

“There’s a really simple induction process – the technology is not foreign because we all live on our phones – and on the back end we can help,” Rosback said.

“There is a small window of opportunity for picking but this actually extends into pruning as well and other scenarios.

“Very rarely in any situation do you see a win, win, win so we were fortunate to be able to experience that.”

Taglog was among seven wine tech startups to participate in the inaugural FOMENT program billed as ‘Australia’s wine and tourism tech revolution’ in Adelaide last month.

Funded by the South Australian Government and hosted by Flinders University, Hydra Consulting and Wine Industry Suppliers Australia, the seven companies were put through an intensive three weeks focused on industry connection, market validation, global scaling and prototyping using Industry 4.0 processes.

Taglog has also established a presence at Stone & Chalk’s co-working space in Adelaide’s Lot Fourteen innovation neighbourhood.

Taglog General Manager Mark Snelgrove said the FOMENT program helped him discover that Taglog needed some kind of partnering or investment to take it to the next level.

“It’s a critical time for us to be part of a program like FOMENT because it allowed us to understand our business model, critique it, be critiqued and then put a strategy in place to help us understand what we need to do to activate the next level of the Taglog business.

“Our business model is for the domestic market at the moment so while we’ve got some opportunities to go to the export market we haven’t got the business model to suit that right now but with the right investor we could certainly scale up pretty quickly.”

Jump to next article